الكيمياء الحيوية وتكنولوجيا الاغذية

Ethanol Production

1. Introduction:

The sugar production as well as world sugar price is subject to continuous and substantial fluctuation. To stabilize economy of sugar producing estate, alternative supportive industries and new source of revenues should be found.

One of the alternatives is utilization of the sugar by-products, which will increase the turn over by 30%. Therefore it’s a necessity to consider optimal utilization of by products as an alternative to mask changes in returns from sugar industry.

The possible alternative is transformation of molasses to ethanol; recently a distillery will be attached to the factory as one of the urgent solution to mask changes in sugar production cost.

2. Ethanol Production (Industry Statistics):

The report on world ethanol, from Renewable Fuel Association (2007) can be summarized as flows:

· Historic U.S. Fuel Ethanol Production

Historically fuel ethanol production in U.S. increases from 175 million gallons (MG) in the year 1980 to 4855 MG in 2006.

· Ethanol Industry Overview

In the U.S. the total ethanol plants increase from 50 in the year 1999 to 110 in 2006 and recently (2007), it reaches 130, with increasing capacity from 1701.7 MG since 1999 to 5493.4 MG and recently it’s 6883.4 MG.

· The World Ethanol Production

The world ethanol production increases from 1077 MG in the year 2002 to 13489 MG in 2006, with Brazil And U.S as the main producers as per summary below:

|

|

It’s obvious that Brazil and U.S. produce more than two third of world production.

- U.S. Fuel ethanol imports by country (MG):

-

Country

2002

2003

2004

2005

2006

Brazil

0

0

90.3

31.2

433.7

Costa Rica

12

14.7

25.4

33.4

35.9

El Salvador

4.5

6.9

5.7

23.7

38.5

Jamaica

29

39.3

36.6

36.3

66.8

Trinidad

0

0

0

10.0

24.8

Total

45.5

60.9

159.9

135.0

653.3

U.S is one of the main producers and importers

· Ethanol Price:

Most ethanol is sold under long-term contract, on private agreement between producers/marketers and petroleum companies. According to industry observers, roughly 90 to 95% of ethanol is sold under these long-term contracts (6 to 12 months). Many of the contracts are “fixed price.” In other words, the price petroleum pays for ethanol doesn’t change, regardless in the spot (wholesale) market price. Some of these contracts may be ‘pegged’ to a gasoline price benchmark. In this case when wholesome gasoline price move up or down, a petroleum company pays for ethanol moves accordingly.

3. Ethanol Production Routes:

Ethanol is an important chemical feedstock, from which a number of industrial products are derived. It’s also used as a petrol substitute for transport vehicles. Ethanol can be produced synthetically as petrochemical product through hydration of ethylene or through bioconversion route. Due the increasing price of ethylene, ethanol, produced from biomass source and it’s known as bio-ethanol. The economics of ethanol production depend on the availability of raw materials, cost of petrochemicals, and plant operating cost.

4. Feedstock’s for ethanol production:

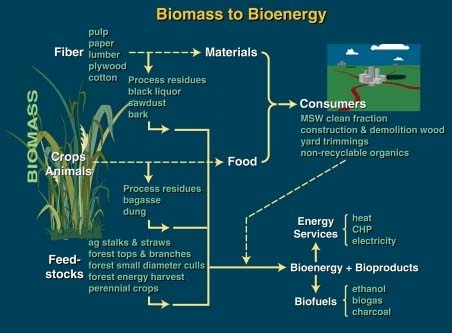

Biomass as solar energy stored can be used as a feedstock for ethanol production; this can be looked in the diagram below:

In U.S at present production technologies rely on sugar and starch feedstocks. Suitable ethanol crops include corn, wheat, grain sorghum, sugarcane, sugar beets, sweet sorghum, and Jerusalem artichoke. Other feedstock includes potatoes, cassava, wood, maize, millet, rice and cheese why. The table shows the amount needed to produce 100 liter of ethanol from different feedstocks:

Feedstock Amount Feedstock Amount Cheese Why 4000 liter Sweet sorghum 1400 kg Sugarcane 1270 kg Jerusalem artichoke 1250 kg Sugar beet 1030 kg Potatoes 850 kg Cassava Molasses Maize Sorghum Paddy rice 545 kg 360 kg 258 kg dry milling 240 kg 225 kg Wood Maize Wheat Millet 385 kg 268 kg wet milling 260 kg 230 kg

M.Regis Lima Verde Leal (2005), showed a comparative energy balance in ethanol production between corn, switch grass, and sugarcane. In which sugarcane gives highest energy ratio and corn is the least. It’s also indicating that sugarcane and switch grass are more effective in ethanol producing than corn.

Process Corn (GJ/ha.yr.) Switch grass (GJ/ha.yr.) Sugarcane (GJ/hay.) Crop production energy consumption 18.9 17.8 13.9 Biomass energy 149.5 220.2 297.1 Agricultural energy ratio 7.9 12.3 21.3 Ethanol production energy 47.9 10.2 3.4 Energy in ethanol 67.1 104.4 132.5 Total energy ratio 1.21 4.43 8.32

Source WWF Workshop-London, June 23-24, 2005

5. Bio-ethanol:

Energy policy targets meanwhile trigged a boom for bio-ethanol all around the world.

Bio-ethanol is readily available clean fuel additive, which used in combustion engine. It can be utilized in different ways:

· Hydrous ethanol (95%by volume) contains some water. It’s employed directly as a gasoline substitute in cars with modified engines. Hydrous ethanol is also called industrial alcohol and can be used to produce a variety of chemicals as shown below.

Chemical processing products:

Acetaldehyde, acetic acid, acetic anhydride, esters, ethers, ethyl chloride and PVC

Biochemical processing (Fermentation processes)

Vinegar, acetic acid, esters; e.g.

· Anhydrous (or dehydrated) ethanol is nearly free of water 99.8% pure. This ethanol can be blended with conventional fuel at a ratio between 5%(E5) to 85%(E85). E5 can be used in modern engines without modification. High blends require modified engines as run, on so called flexible fuel engine.

· Finally, bio-ethanol is also used to manufacture ETBE (ethyl-tertiary butyl-ether), a fuel additive for conventional gasoline.

6. Benefits from bio-ethanol:

Benefits of bio-ethanol include:

· Renewable resources

· Impact on air quality due to cleaner combustion

· Reduced net carbon dioxide (greenhouse gas) emissions

· Energy security; less dependence on crude oil

· Expanded market opportunity in the agricultural field

7. Overview of ethanol production in Kenana

Sugarcane was considered as highly efficient converter of solar energy, and has highest energy-to-volume among energy crops. Indeed it gives the highest annual biomass energy yield of all species. Roughly, one tone of biomass based on bagasse, foliage and ethanol outputs has energy contents equivalent to one barrel of crude oil.

In terms of green energy then, its clear that the major cane biomass, energy chain in sugarcane industry:

· Cane juices / molasses for conversion to ethanol

· Bagasse for heat and electricity generation, and / or to ethanol and lignin for co-generation

· Stillage / vinasses for conversion to methane gas (Bio-methane) which is used for electricity generation

Furthermore, anaerobic digestion of filter mud for production of methane gas for power generation, or composting to organic fertilizer by mixing it with vinasses.

The research revealed that about 90% yield of ethanol is possible, from Kenana final molasses, which is equivalent to about 270L per ton of molasses. The sugar factory produces on average 750 tons of molasses per day, and 140 thousand tonnes per year. For ethanol factory of production capacity of 200 thousand liter per day 700 tons of molasses is required. The total amount of the final molasses is enough for about 200 day. To run the ethanol factory more economically and with increasing revenue it should be run for 300 days. To fill the shortage gab we should look some alternatives.

8. Alternatives feedstock:

The alternative feedstock material to run KENANA ETHANOL FACTORY for 300 days includes:

· Diversion of mill secondary juice to ethanol production

· Diversion of secondary juice from rotary filter, for production of ethanol.

· Other sources of feedstock

Solution One: Utilization of secondary juice for ethanol production

Under, Title Economics of Sugar, Ethanol, and Power Mix. The Technology Information, Forecasting and Assessment Council (TIFAC) of India, (Department of Science and Technology), mentioned that, directly using the secondary juice for ethanol production is the most economical and value added concepts of sugar factories. The secondary juice is a dilute, has less sugar and carries impurities, therefore it requires a substantial amount of steam for evaporation and induces more load on the sugar refining operations. By diverting this secondary juice to produce ethanol it will help Kenana in:

· Reducing the load of evaporation of this diluted juice, thus reducing steam consumption.

· Reducing chemical consumption in the evaporators

· Reducing the load of the refining operations

· Producing best sugar quality for export

· By utilizing secondary juice for ethanol production additional stock of molasses will be saved to fill the gab in molasses shortage, therefore the ethanol factory can be operated for 300 days.

· Value addition in terms of additional revenue generation by selling ethanol

The above scenario is now running in India to improve economics of sugar, and ethanol mix of sugar industry and TIFAC (Department of Science and Technology), give and assumption that can be applied to Kenana.

Taking 100 tons of cane as a base for calculation, revenues will be increased; this can be shown in the comparison between, the diverting secondary juices for ethanol production and the conventional process of mixed juice for sugar production, and only final molasses for ethanol production

Taking a base of 100 tons cane per hour (TCH)

Crushed cane 100 TCH

Pol. in cane 12.5 %

Sugar recovery 10.6 %

Mill extraction 95 %

Primary juice 70 %

Secondary juice 25 % (Equivalent to 2.7 tons sugar)

Final Molasses 4 %

On the light of the above assumption:

Ethanol yield can be obtained from 25 tons (2.7tons sugars) secondary juice equal to:2710 liters

Ethanol yield of from 4tons molasses 48%sugars (1.92 tons sugars) equal to: 1021 liters

Case (1)

Utilizing secondary juice for ethanol and primary juice for sugar production manufacturing process.

|

|

Case (2)

Normal sugar production using clarified mixed juice for sugar manufacturing and using final molasses for ethanol production.

Product Qty Rate /SSD Revenues /SSD Sugar 10.6 tons 140062 per ton 1484657.2 Ethanol 1021 litre 200 per litre 204200 Excess power 9.3MW 20000 per MW Revenues 186000 1874857.2 =y

The total revenues per 100 ton of cane equal to x-y = 29632.6 SSD

The total revenues equivalent USD = 147.426 USD

Considering the average cane processed by kenana in the last three years (3749484 tons). Therefore the total revenues can be calculated as follow:

Total cane/100*147.426= 37494.84*147.426 = 5527714.282 USD

It’s obvious the above increase is considerable more the five million US Dollars per year.

The above scenario when applied to kenana above, to the advantage mentioned before and increase in revenue, molasses of high purity will be saved as stock for off crop ethanol production and it will be about 100 thousand tones, which is enough to run the ethanol factory for further 140 days after the crop end.

Solution Two: Utilization of clarified juice for ethanol production

The diversion of mud filtrates juice to ethanol production, was considered as a mean factor for survival for Rocky Point Sugar Mill In Australia (David Heck, 2003) with the advantage of:

• Steam saving

• Increase in crushing rate due to reduced impurity recycling

• Better quality sugar

• Stock molasses for off-crop ethanol production

The procedure involves taking filtrate stream to ethanol production, cooling to 350C and incrementally filling the fermenter while keeping the brix below 300, and temperature below 320C. The fermenter was set to achieve a 10% ethanol yield adjusting fermentable accordingly (90% fermentation yield), approximate ratio 1:5 molasses: filtrates. Fermentable in filtrate was 10% and molasses 48%.

The advantage mentioned above can be gained by kenana to fill the gab of molasses shortage during off-crop. The stock will be about 80% total molasses produced by kenana, it’s equivalent to112 thousand tonnes, and this amount is enough to run the ethanol factory for 160 days after the crop ends.

Solution Three: Using other crops

Ethanol can be produced by different ways using a variety of feedstock. Crops of higher yields of energy such as switch grass and sugarcane are more effective in producing ethanol than corn. Ethanol can also be produce be produced from sweet sorghum, a dry land crop that use much less water than sugarcane and produces food, and fodder in addition to fuel ethanol.

Basic steps for dry mill production of ethanol from corn are: refining into starch, liquefaction and saccharification (hydrolysis of starch into glucose), fermentation, distillation, dehydration, and denaturing (optional).

Carbon dioxide, a potentially harmful greenhouse gas is emitted during fermentation. However, the net effect is more than offset by the uptake of carbon gases by the plants grown to produce ethanol. The net result of using ethanol as a fuel is to reduce green house gasses.

It’s obvious that one and two are easy and the feedstock is at hand and requires only setting of processing parameter. While other alternatives require preparation process, e.g. corn and cereals

9. Over view of environmental impact mitigation

Kenana dispose on average the following solid waste:

About 110 thousand tons of filter mud

And 10 thousand tons of ash readily collected at the boiler end through ash collector.

It is possible to remove, the environmental impact of filter mud through composting it with vinasses (distillery wastewater).

Distillery wastewater:

Before implementing a distillery we should think of the waste generated, which is variously called spent wash, vinasses, stillage, slop or wastewater. Depending upon the process used for fermentation and distillation, its volume varies from 6 to 15 liters per liter of ethanol. The characteristics of wastewater, like COD and BOD5 and dissolved solids also varies accordingly. Therefore the first step in mitigation of distillery waste is to select fermentation process of less wastewater discharged without affecting ethanol yield.

The wastewater generated from distillery can be mixed with filter mud as it discharged from the distillation plant to be composted into organic fertilizer. Therefore the sprit of environmental hazard of both filters mud and distillery waste can be totally removed. By recycling the organic fertilizer to cane field’s organic sugar of high marketing value can be produced. The excess amount of the fertilizer can be sold.

On the light of the above view experiments was conducted as follows:

Production of methane gas from filter mud, through fermentation process and sun drying of the resulted waste to organic fertilizer. Production of organic fertilizers by composting of filter mud and distillery wastewater (vinasses).

Treatment of distillery waste through concentrations and chemical supplementations process and drying it to organic fertilizer.

The result achieved gave products of NPK ratio enough to enhance growth of soil nitrogen fixing bacteria plus about 80% organic matter. The analysis of product revealed compositions:

1. Nitrogen % = 0.88

2. Phosphate % = 2.70

3. Potassium % = 3.00

4. Organic Matter % = 80.50

5. Inorganic Matter % = 19.50

It was found that we require 470.8 million liter of vinasses to compost all the filer mud of discharged from kenana sugar factory, which is approximately equal halves the amount resulted from ethanol factory, furthermore the other part can be processed to produce 160 tons of organic fertilizer per day. Takeshi Saito (1979) show a process developed by Kyowa Hakko Kogyo Co. Ltd. for producing organic fertilizer from vinasse. The process, include concentration, acid treatment (using sulfuric acid), neutralization (using liquid ammonia), kneading by mixing with calcium phosphate, granulation and drying as a main processing steps. Akio Yemazoe (1979) mentioned that 160 tons organic fertilizer can be achieved from vinasse discharged from production 100 million liter of ethanol per day. Also concentrated vinasse can be used as supplement in animal feed factory as its rich in protein.

11.Other Methods For Vinasse Treatments

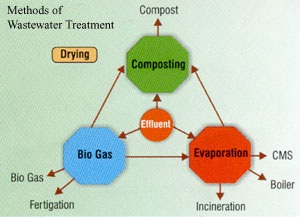

The PRAJ Industries limited (India) grantee a combination for distillery wastewater treatment system e.g.

1. Fluidised Bed Evaporation

2. Fluidised Bed Evaporation plus composting

3. Fluidised Bed Evaporation plus energy Recovery Boiler

4. Bio-methane plus composting

5. Bio-methane plus Reverse osmosis plus composting

6. Composting

7. Reverse osmosis plus composting

The diagram below shows these combinations: